A message from the head of the Department of Sustainable Biomaterials

November 15, 2018

Robert L. "Bob" Smith

The forest products industry has always been vital to our nation’s and the commonwealth’s economy. It is estimated that more than 100,000 citizens are employed in Virginia’s forest products industry, which contributes more than $21 billion to our economy annually. Recognizing the importance of forest resources and wood products manufacturing, Virginia Tech established the Department of Wood Science and Forest Products nearly four decades ago to train students to enter this field.

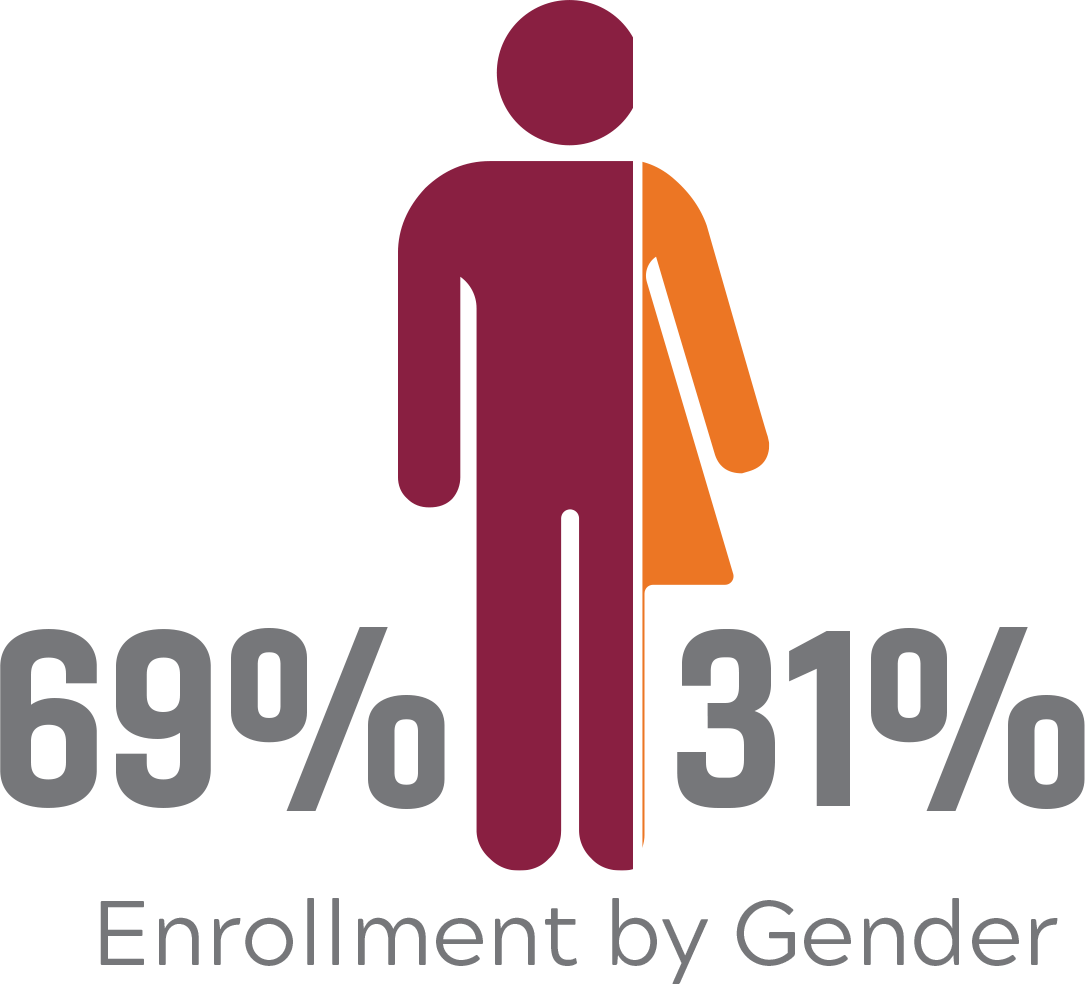

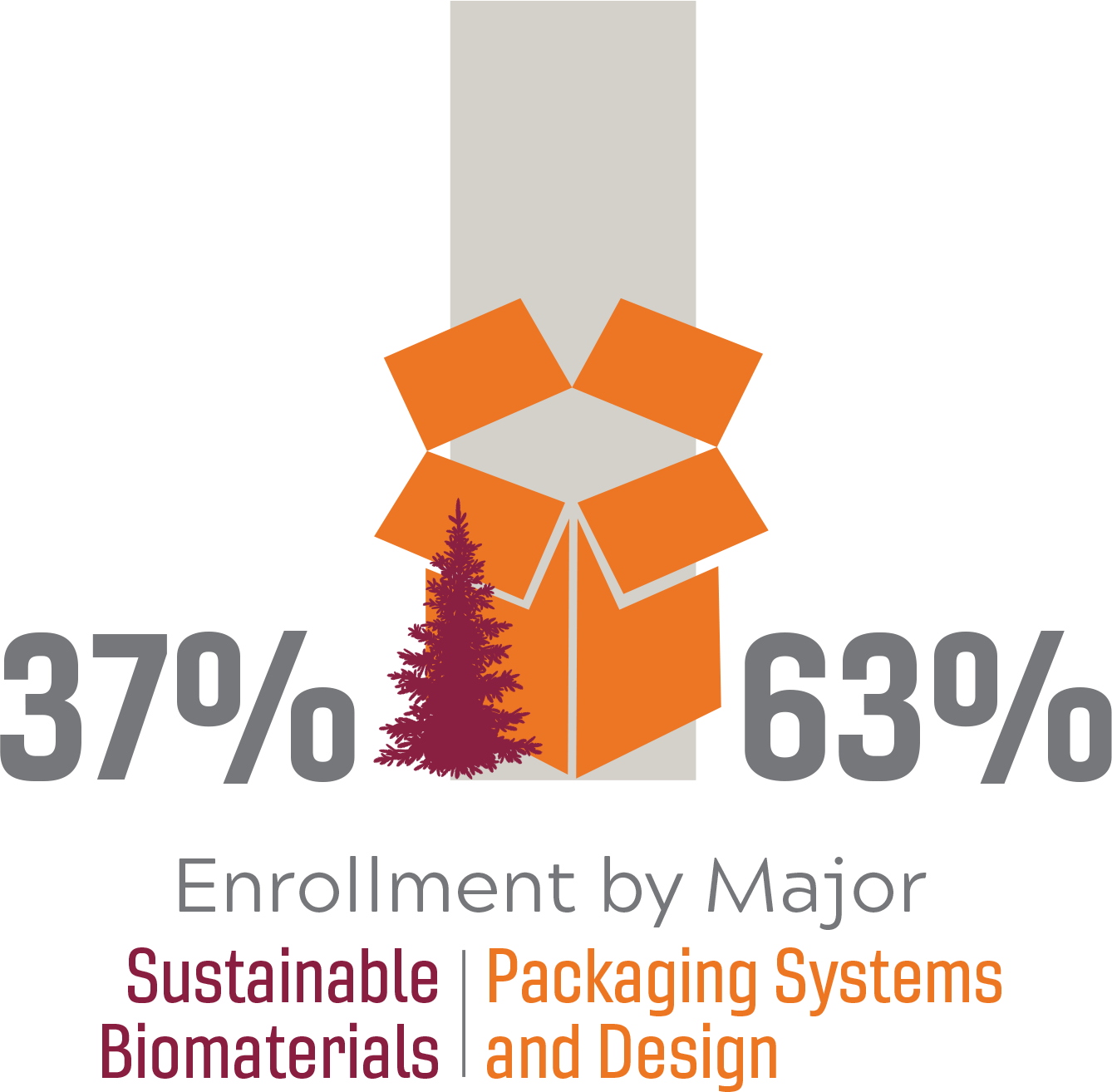

We have evolved over the years in service to our students and the industry. We changed our name to the Department of Sustainable Biomaterials in 2012 to better reflect our faculty’s expertise and broaden our appeal to a changing student population, and established two separate degree programs in 2014. The sustainable biomaterials degree, which reflects our past wood science program, retains its focus on teaching the fundamentals of the processing, manufacturing, drying, and marketing of wood and other biomaterials. The packaging systems and design degree emphasizes the importance of the sustainable use of packaging materials, how packaging can enhance product performance and markets, and how new uses of wood fiber can be used to replace petroleum-based plastics.

With nearly 200 undergraduates and 18 faculty members, we are one of the largest programs in North America. Our students are in high demand from the forest products and packaging industry. Students have many opportunities for industrial internships, hands-on experiences such as running a business with our Wood Enterprise Institute, and numerous study abroad courses that expose them to the international aspects for forestry and forest products. Owing to these efforts, we received one of three Exemplary Department Awards from the university in 2017.

The department continues to have one of the largest wood products cooperative extension programs in the country. Our extension specialists cover all aspects of wood manufacturing, drying, secondary processing, business management, and marketing. They regularly conduct mill studies and offer workshops to help the lumber industry increase its competitiveness.

Our name and degree programs have evolved over time, much like the products and industry that we rely on for the many consumer goods. Preparing students for successful careers is our most important goal so they can help our industry remain competitive in a global marketplace.

Did you know?

- Packaging is the largest use of wood fiber in the world. Our packaging systems and design program is teaching students about better ways to design, produce, and recycle packaging materials.

- Our scientists are using the building blocks of wood (cellulose) to develop targeted drug delivery methods for cancer treatments as well as nanoscale materials for bone repair scaffolds.

- Our wood engineering faculty are testing new species of lumber for use in cross-laminated timber panels, which are now being used to construct buildings over 18 stories high.

- Our packaging faculty run on of the largest pallet and unit load testing facilities in North America. Six to 12 student interns conduct the majority of testing in the lab, under faculty supervision.

- Our extension faculty help forest products companies implement lean manufacturing techniques that can lead to better production efficiencies, less waste, reduced energy consumption, better product throughput, and reduced operations costs.

- Our students learn that wood is the most environmentally friendly, sustainable building material and that it helps store carbon and reduce greenhouse gas emissions.

- Our Sustainable Biomaterials program is one of the largest of its kind in North America. Our students are preparing to enter the forest products, packaging, and sustainable materials sectors to help create a sustainable future.

Sustainable Biomaterials

by the numbers

2018 Fall Enrollment

179 Undergraduates

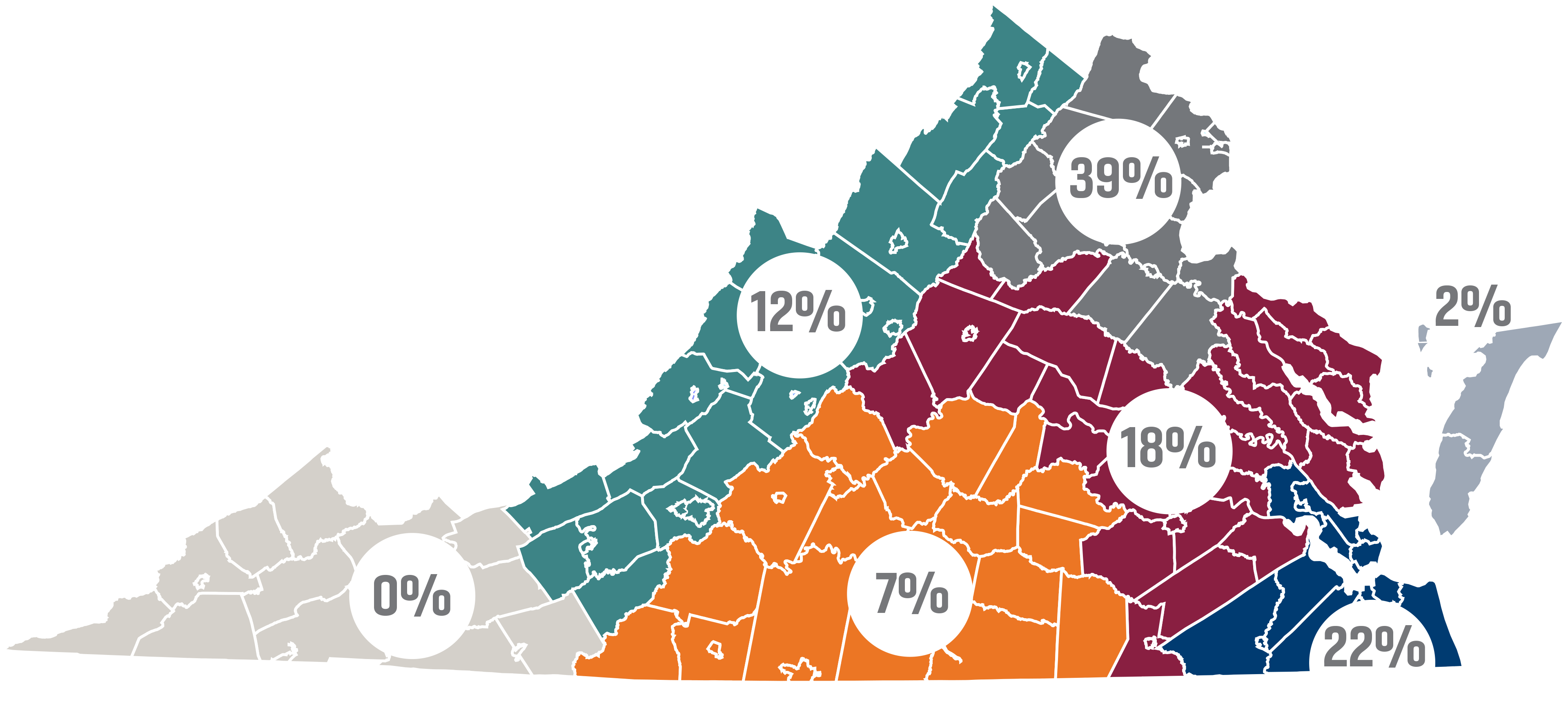

In-state Student Residency by Region (68% of Total Students)

FreshmAn Admission

Applied

Offered

Enrolled

Offered Rate

Yield

Full-Time Faculty

15 Tenure | Tenure-Track

3 Scientists | Postdocs

18 TOTAL